|

| A Black Brant V sounding rocket, from Wallops Flight Facility, parked all weekend outside NARCON |

Plus, there was a real NASA sounding rocket - the Canadian-built Black Brant V, seen above - on display in the parking lot outside all weekend. This in fact caused a bit of a stir, when an F.B.I. agent driving by noticed the hulking rocket sitting in a hotel parking lot, got a little suspicious about this, and called the police. NAR officials quickly cleared this up, and the police apparently had a bit of a laugh about the whole thing.

This year's convention was hosted by NOVAAR - the Northern Virginia Association of Rocketry - and they put together a great event.

|

| Orange and black are the official colors of NOVAAR. |

I arrived at the hotel around 11:30 in the morning on Friday, and met CG, co-host and creator of The Rocketry Show podcast, for the first time. Despite the fact that we're on the same show, we'd never met in person before.

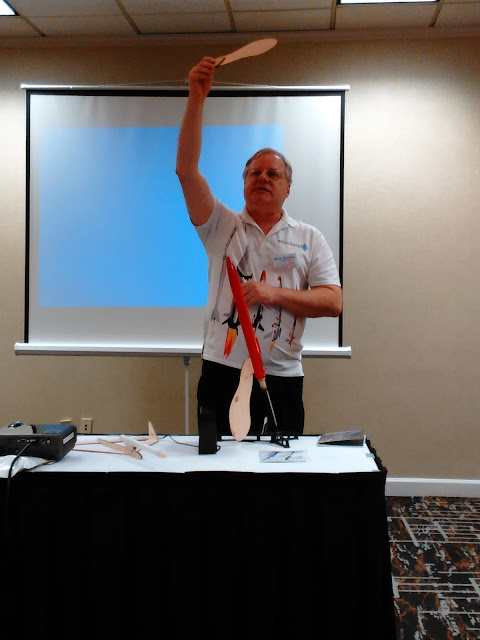

He gave me my official Rocketry Show shirt to wear at the weekend's events. It's pretty nice!

We went to the Udvar-Hazy Center to look around and record some video and audio for the podcast, including the teaser video I posted yesterday.

Friday night began with a town hall meeting where NAR president John Hochheimer discussed the state of the NAR and the board's pre-NARCON decisions about the organization. Membership continues to reach record highs, and the organization is in good financial shape.

This was followed by Research and Development presentations. This is a competition event for those wishing to present projects on technical development in the hobby, and presenters were vying for $1,000 in cash prizes.

International competitor Stoil Avramov showed techniques he uses for building incredibly light, perfectly airfoiled wings for competition rocket gliders. Building up wings from multiple materials - a foam core and various materials for skins and hinges, he has perfected wing building.

My camera had a hard time with some of the lighting this weekend, so some of these photos are a little blurry.

|

| Stoil Avramov shows off one of his competition rocket gliders. |

These are very lightweight rockets. Matt made a couple of interesting points. For best altitude, it is best to have the booster (first stage) as light as possible. If it were possible to have a massless booster, that would be best.

But a sustainer (upper stage) performs best between about 9 and 11 grams. That is the optimal mass.

Another interesting result of the analysis has to do with the timing of the staging. Multistage model rockets typically use direct staging, in which the lower, booster stage rocket motor ignites the upper stage motor, when the propellant burns its way through the top of the motor. There is no delay grain or ejection charge - just a propellant grain which is exposed at the top of the motor.

|

| Image from yoctopuce.com |

As such, there is only about 0.001 second between burnout of the lower motor and ignition of the upper motor (this 0.001-second delay was actually described by Trip Barber during his college days - the work I mentioned above - and is thus known as the "Barber delay"). In other words, staging is nearly instantaneous.

By doing this, the upper stage model is "launched" in midair, but already traveling upward very fast. Therefore, the velocity of the boosted rocket is added to the sustainer or main stage, giving the model a much higher performance than if it were launched standing still.

High power rockets and those that use composite propellants, however, often have a delay between the lower stage burnout and upper stage ignition. The booster will burn out, the stages will separate due to the drag on the lower stage, and the upper stage is then ignited by an electronic system carried on the rocket itself.

What Steele said is that, according to his analysis, there would actually be an altitude advantage on an FAI competition model if there were such a delay between booster burnout and sustainer ignition. This surprising is in contrast to what most people assume, because of the way staging is described in The Handbook of Model Rocketry. The reason is that most people forget that when describing the altitude gains in direct staging, G. Harry Stine was assuming that there was no aerodynamic drag. By increasing velocity of the rocket, you increase drag dramatically. Therefore, there is an advantage gained by allowing the rocket to coast a bit between booster burnout and sustainer ignition - provided the rocket doesn't begin to arc into the wind, of course!

In reality, delayed staging like that is impractical in a contest rocket, because there is a weight penalty. The electronics needed to ignite the upper stage would add mass to the rocket.

Tim Van Milligan of Apogee Components presented a computer analysis of drag on launch lugs, launch rail buttons, and launch rail guides. I was really interested in this one. I have seen in online forums that a lot of people assume that rail buttons create less drag than launch lugs. A lot is made of the drag of launch lugs, including in The Handbook of Model Rocketry. But to my knowledge, the drag of lugs and rail buttons had never been put to the test, and it seemed that everyone was assuming that buttons are of lower drag.

I won't go into too much detail here, because this subject will almost certainly be the topic of an upcoming Apogee Components newsletter. But I'll just say that, according to the airflow computer simulation software he used, Van Milligan found that launch lugs have the lowest drag, while rail buttons have the highest. Launch rail guides are in the middle.

Some other interesting findings - airfoiled rail buttons (such as the one seen above) actually do have lower drag than standard buttons, and the drag can theoretically be lowered further by rounding the sharp edges on the tops of them, and launch lug drag can be lowered further by shaping as well. Also surprising, long launch lugs appear to create less drag than short lugs.

|

| Don't be fooled by these numbers. Simulations were run on an extra large simulated model to get more clear information. |

Dan Wolf presented his project, creating a digital pressure sensor emulator, which he hopes to use in altimeter testing. This is to verify the accuracy - and consistency - of various commercially-available altimeters.

And Chris Flanigan, another contest flyer, presented comparisons of predicted and flight data for rockets flying from an 18mm piston launcher (a piston launcher is used in contest rocketry instead of a traditional launch pad and rod. It uses the motor's gasses to impart more velocity to the rocket at liftoff in an attempt to reach higher altitudes).

First prize went to Chris Flanigan, second to Stoil Avramov, third to Matt Steele, and honorable mention to both Tim Van Milligan and Dan Wolf.

The Breakout Sessions

On Saturday, the breakout sessions took place. There were four "tracks" you could choose from: TARC Rocketry, Professional Rocketry & Spaceflight, Model Rocketry, and High Power Rocketry.

Honestly, it was sometimes hard to choose what to see. There were seven scheduled hour-long sessions with one session in each track, so you could see up to seven presentations. I made it to five in total. I wish I had seen others, but CG and I needed to record some stuff for the podcast.

We chatted with the vendors in the Vendors Display Room. Those conversations will be on the forthcoming podcast. I saw presentations on NASA's sounding rocket operations, Tim Van Milligan's demo of doing a lightweight fiberglass layup for FAI contest rockets, and a presentation on painting and finishing which was really aimed at TARC rocketeers (this year's contest rules include the requirement that all rockets must be colored somehow or another - be it paint, marker, colored tape, Monokote covering, etc).

|

| Carl Curling describes how this TARC rocket was finished and painted. |

Later in the afternoon, I went to hear Jim Barrowman speak in a TARC Rocketry session. Barrowman created simplified mathematical equations for finding the center of pressure on a model rocket, which enabled rocketeers to create designs and know they would be stable in flight. His work is used in all rocket simulation software today, such as RockSim and OpenRocket. He based these equations - what became known as "the Barrowman equations" - on his work with sounding rockets.

The room was packed. He said at the outset that the session would cover the basics in Centuri TIR-30, and would not be about the Barrowman equations, and that he would understand if anybody felt bored or left. Of course, nobody did!

After the session, Jim came to the Vendor's Room where CG and I had set up a table to record, and he was gracious enough to grant us an interview. I turned to him as we were setting up and said "I have to admit that I'm pretty nervous."

But he was so easy to talk to. Jim Barrowman is a really approachable person, and we ended up having a great conversation. Once we ended the interview, we continued chatting, and had a conversation that I can only describe as delightful. CG said "I should have been recording this!"

|

| Me, Jim Barrowman, and CG. Meeting this man was worth the whole trip. |

But the interview was terrific, and I really think you'll enjoy it.

The Manufacturer's Forum

Some of the most exciting news came from the Manufacturer's Forum at 5p.m. There were nine vendors there to discuss new products, and each had a limit of five minutes to present. Here are the ones I think readers of this blog will find most interesting.

Jolly Logic

Jolly Logic has a number of exciting things in the works. First, the next iteration of the Chute Release will include more ergonomic, easier-to-use buttons. New bands and chute deployment bags for larger chutes for high power are being developed.

Second, a smaller version of the Chute Release is in the works! This was hinted at on Twitter a while back, and John Beans is currently working on it. He has to build a whole new servo in order to do it. The current Chute Release uses the smallest servo he can find. But the good news is that the new Chute Release should fit into a much smaller tube, and due to being smaller, should be less expensive than the current Chute Release. Both of these are great selling points, especially for model rocketeers with a fleetfull of smaller sized rockets. The new Chute Release will probably not be out this year, but likely in 2018.

What should be released sooner, however, is the Altimeter Four. Before Chute Release, Jolly Logic was primarily known as a maker of versatile, easy-to-use altimeters. Here is a photo of my Altimeter Two, which weighs about 10 grams.

It's a great altimeter which gives a lot of interesting flight information. But at 10 grams, it can be a little heavy for smaller low power birds.

Well, here is a 3D printed "size model" of what Altimeter Four will look like.

Altimeter Four's projected weight - one gram! Not only that, it will connect to a computer or phone and give all the flight analysis information you'd expect from a Jolly Logic altimeter, including a flight profile in graphic form like the Altimeter Three.

[EDIT] I nearly forgot to mention that John is working on a GPS location solution for rockets. Knowing how easy Jolly Logic stuff is to use, I can't wait for this to come out! It may take some time, but I'll definitely put it in the shopping cart.

[EDIT] I nearly forgot to mention that John is working on a GPS location solution for rockets. Knowing how easy Jolly Logic stuff is to use, I can't wait for this to come out! It may take some time, but I'll definitely put it in the shopping cart.

AeroTech

AeroTech has a number of exciting things coming out - both new kits and new motors.

The four-inch diameter Monstra will be able to fly Level 1 and Level 2 HPR flights with its 38mm diameter motor tube, and four-inch airframe. It features a recovery harness from One Bad Hawk.

And the beautiful "fantasy scale" Arreauxbee-Hi is a cross between the AeroTech Arreaux and an Aerobee-Hi scale model. It flies on 29mm motors, and I wanted to take it home with me.

The new kits include screw-on motor retainers instead of motor hooks, and also have both launch lugs and rail guides, so the rocketeer has the option of either one without having to purchase additional hardware separately.

A new single-use F motor is debuting soon, the F67 Economax. Why an F? Gary Rosenfield, the owner of AeroTech, explained it was their attempt to get the most power they could from 30 grams of propellant. 30 grams is the most that can be legally shipped via the US Postal Service, rather than via UPS with a HAZMAT fee.

The 14-second delay won't be featured. Delays will be 4, 6, and 9 seconds.

The 14-second delay won't be featured. Delays will be 4, 6, and 9 seconds.

Speaking of US Mail shippable motors, another exciting development by AeroTech for HPR fliers is a non-HAZMAT J motor! This is pretty unusual, and it's accomplished by dividing the motor into 13 individual 30 gram propellant grains.

This, says owner Gary Rosenfield, will be about as far as they'll go with that, so don't expect a mailable M motor any time soon!

As for the Quest Q-Jet composite model rocket motors, they only had on display the A3 motors, which have passed certification, but the others are still waiting to finish the process. They'll all be released at the same time, once all motors have been certified. According to Gary, this is one of the hardest motors AeroTech has made, but it will be exciting for us when they are finally available.

Apogee Components

Tim Van Milligan announce Apogee's intent to release ten new kits this year. Apogee is hiring a marketing person and a web developer.

Aerospace Specialty Products

ASP showed off some of their new 29mm powered mid powered scale kits. These weren't new at NARCON, but it was nice to see them in person, particularly the Sandia Sandhawk, the D Region Tomahawk, and the WAC Corporal models. These are pretty simple kits that a relative beginner can assemble without much trouble, but with accurately-sized parts so that an experienced builder can add details and have a very faithful scale model.

Due out mid to late summer are three more scale kits, details of which will be announced later.

eRockets (including Semroc)

There are now 125 Semroc kits through eRockets, and the number continues to grow.

The Maple Seed is a sort of odd-rock with maple seed-shaped fins. At apogee, the seed-shaped fins detach and helicopter down, just like the real thing.

Also coming out later this year, provided Estes doesn't change their mind and re-release it, will be a Semroc version of the Scissor Wing Transport, a boost glider which always had a bit of trouble flying just right. Randy Boadway of eRockets says he's solved the problems with the Scissor Wing, and it should be flyable more than once or twice.

Chad had an Estes Scissor Wing Transport, and I can tell you that it was tough to get it to fly right.

North Coast Rocketry

Dr. Zooch

Matt Steele presented a new kit, an upscale of the Estes Goblin, called the Hobgoblin. It will fly on 29mm motors. It's actually a much smaller version of a North Coast Hobgoblin from years ago, which was 8 inches in diameter. This one is pretty fun and still nice and fat at 2.6 inches in diameter.

Also coming soon from NCR are 29mm screw-on motor retainers similar to those sold by Estes, but with rocket nozzle details attached, so your mid power model rocket can look more like a space launch vehicle.

Dr. Zooch

Wes Oleszewski of Dr. Zooch presented at the Manufacturer's Forum. While they won't have any new kits, Wes does have a series of books on the history of spaceflight, Growing Up with Space Flight (click here for an example).

You'll hear more from Wes on the upcoming podcast.

You'll hear more from Wes on the upcoming podcast.

* * *

At the banquet, Lee Piester of Centuri Engineering, told the story of his time running a much-loved model rocket company. It was an inspiring story with some surprising details, and even made me nostalgic for Centuri rockets, even though I was far too young for rocketry when Centuri did most of its business, being nine years old when the Centuri line was finally discontinued.

We hope to have Lee Piester on the podcast soon.

Door prizes were handed out. John Beans had donated ten Jolly Logic Chute Releases, and while I didn't win one to replace my lost one, as I'd been hoping, I did in fact get a pretty great prize for me - a copy of Tim Van Milligan's book Model Rocket Design and Construction, something to add to the library.

Door prizes were handed out. John Beans had donated ten Jolly Logic Chute Releases, and while I didn't win one to replace my lost one, as I'd been hoping, I did in fact get a pretty great prize for me - a copy of Tim Van Milligan's book Model Rocket Design and Construction, something to add to the library.

* * *

After the proceedings on Saturday, I sat in the hotel restaurant with Bill Cooke of The Rocketeer's Corner blog and had a great chat. Bill's a really nice guy with a fun blog (check out his stuff about "Geezer TARC"), and we shared modeling tips - well, mostly I asked him how he builds such nice looking rockets.

Sunday I returned to the museum with those who stuck around, and stayed there for five hours, looking at planes, models and space ships. It was a perfect weekend, and I managed to only spend slightly too much money.

Thanks to NOVAAR and the NAR for such a fun conference!

Follow me on Twitter.

Like my Facebook page for blog updates and extra stuff.

Have a question you'd like to see addressed on this blog? Email me at iamtherocketn00b@gmail.com.

Follow me on Twitter.

Like my Facebook page for blog updates and extra stuff.

Have a question you'd like to see addressed on this blog? Email me at iamtherocketn00b@gmail.com.