I'm finishing up one of my three latest builds - the Quadrunner, by Quest Aerospace. This is a cool-looking rocket, and has a cluster of four motors - that's a lot of thrust, fire, noise and smoke compared to what I've launched in the past.

Check out what the kit looks like:

I'd been eyeballing this rocket for some time. I loved the idea of clusters, even before I'd tried them out. My first was the Quest Magnum Sport Loader, which was a lot of fun. Even with only two motors, you get a much more dramatic launch than with a single motor.

Here's the video of the Magnum launching on two Estes C motors - slo-mo at the end:

|

| The finished mount |

There's another part that goes in the middle - it holds the bolt in place you see in the above photograph, which will hold the motors in - this is in place of the usual hooks most beginner's models use.

This meant threading the bolt through two diamond shaped bits, attaching a Kevlar shock cord to the top, then pulling the whole thing through the middle of the four motor tubes - then gluing that in place.

|

| This little bit keeps the motor retention system in place, and is key to assuring your parachute ejects. And it's a tight fit. |

It requires some precise sanding to make it fit, and without a precise fit, the ejection gasses from the motors will escape out the back of the rocket. The nose cone won't come off, the parachute won't eject, and the whole thing will come crashing down to earth and destroy all your work.

Then there are the fins. They're two-part fins which you have to glue together to make one piece - something I was nervous about, as I was pretty sure it would be easy to get them crooked.

|

| The joint here needed to be pretty close to perfect. |

I thought of several options, since in the directions you're meant to lay them flat on waxed paper to glue them together flat. I thought no way that's gonna come out straight - it's gonna dry crooked! I finally emailed Chris Michielssen of the Model Rocket Building blog, to ask what he'd do if he built this rocket. I hadn't found any references to the build on his blog, but I knew that if anybody knew what to do, it would be him.

He gave me some advice - turns out he had built this rocket. He said that gluing them flat on waxed paper was a good idea, and then putting a book on top would keep things straight. I sanded a rounded edge on part of the fins, then beveled the trailing edges, and put them together.

So far, so good.

I took all the steps I've learned so far to make the rocket look (and fly) great - carefully filled in those spiral grooves in the paper body tube, filled and sanded and filled and sanded and filled and sanded the fins, attached the fins to the body as carefully and precisely as I could...

|

| Ted Macklin's guillotine fin jig... |

|

| Totally worth the money I paid for it. |

|

| Hi, Ted! |

|

| Was I going to let this little flaw in the nose cone go unfilled? Oh, no I was not! |

Then, I had to wait to do the painting. Or, so I thought.

It's been cold here in Bloomington, and my understanding was that you should never spray paint if it's below 50 degrees Fahrenheit. So I waited.

Then, on a warmer day, I primed the rocket. I used a new primer to me - Rustoleum Sandable Primer. I always use primer that's "sandable," but had never used "Sandable Primer."

Actually, this was my first mistake. It turned out fine, and I really liked the primer. But I had intended to use Rustoleum Filler Primer. This stuff has a "build" to it, and apparently it can fill in flaws in your work. I believe it's used to fill in gouges in a car's paint job. I had a few spots I wanted filled on the fins, and a few weeks ago when shopping, I had been looking at both the Sandable and the Filler Primers. I thought I got the Filler stuff. I realized only after priming the rocket that I'd gone home with the Sandable stuff.

Never mind - it worked great. A few minor flaws that perhaps could have been fixed with the Filler stuff, but after some rigorous sanding, it still looked pretty good.

|

| Warmer than it looks - time to prime |

|

| Primed and sanded, ready for painting |

Round about this time, I got a suggestion on The Rocketry Forum that you can, in fact, paint when it's cold outside. You warm the paint can with some warm water, run outside with the warm paint and rocket, do a light coat of paint, and bring everything inside to dry and warm up for a few minutes between coats.

I had a launch scheduled for Saturday (cancelled, in the end, due to rain), and I thought I'd have time to finish this rocket by then. I always like having something new to launch each time, because I don't have any other rocketeers to fly with - I launch with friends who are only interested because I try to make it fun for them. Basically, every launch I do is a kind of "demonstration launch," and I'm secretly trying to get one of my friends interested enough to start building and launching, so I have someone to talk rockets with.

I wiped the rocket down with rubbing alcohol to rid it of any dust, and did my undercoats of white. The rocket looked great. No problems due to cold weather - a nice, smooth, shiny finish.

|

| It's hard to light a white rocket indoors, but you get the idea. |

This is where the trouble started...

Now, I was going to include this paint job in a post for my fellow rocket n00bs on the fact that you need to plan certain parts of your build, particularly painting, to avoid a messy job, and to keep from being frustrated. In the process, I learned that I have a lot to learn about certain materials with rocket building...

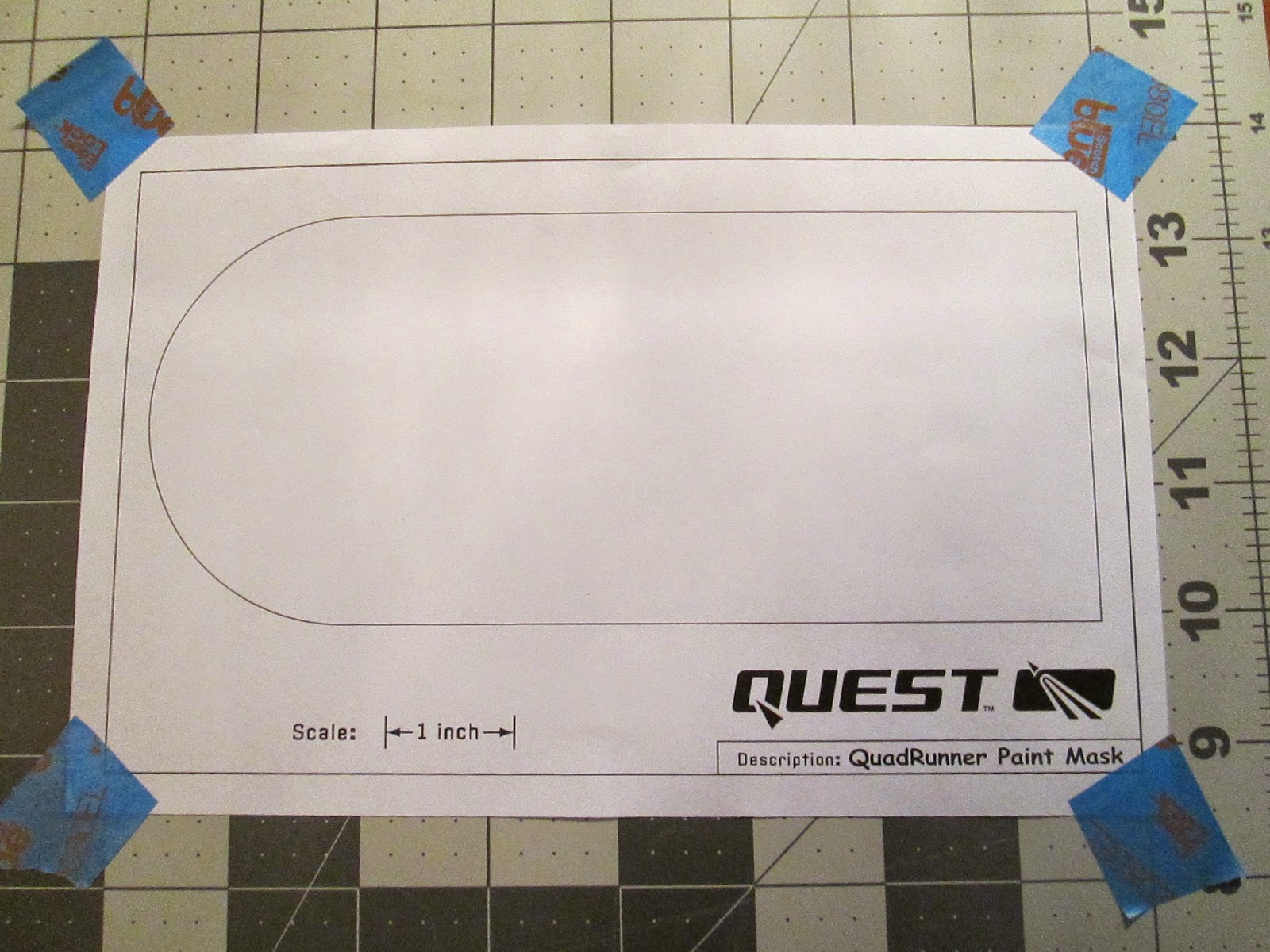

OK, so the Quadrunner comes with a paper mask for painting.

This presented a challenge. How could I be sure to get the mask centered and straight? If I applied it the correct distance from the top, how could I be sure that the part of the round top I started with was even the true center of that bit?

Well, I thought about it a bit, and came up with what I think was a pretty good plan, and I thought this is perfect blog material, too! What a smart guy I am!

First, I measured the bottom of the mask, finding the center of that line. Then, using a right angle, I drew from that point up the center of the mask, through the top.

To check my work, I did a little geometry to find the center of the semicircular top - and you can see was off by just a little bit. I made sure the line was straight up the center from the bottom to the top, and carefully cut out the mask.

I cut up the sides with my hobby knife and a metal ruler. I tried to rig up a tool to do the top round cut precisely, using my high school compass and my hobby knife. I think I found this idea in an old Estes or Centuri rocket design publication I found online.

This didn't work as planned, so I just carefully cut the top out with scissors. Not to worry - the black and gold stickers would probably cover any minor imperfections in the shape.

Then I found the centerline between two fins by measuring the distance between the leading edges of the fins and making a mark with a pencil. Then I drew a line all the way from there to the top of the body tube, and on that line, I put a mark 1 5/8" from the top.

Now I had a line on the rocket, and a line on the body tube. If I could get those lines to match up with the top of the mask at that little 1 5/8" mark, I knew I'd have the mask centered and placed correctly, and we'd be good to go.

|

| See? This should work great! |

I still think this is a good idea, despite what came next...

To apply the mask, temporary spray adhesive is called for. I have some Elmer's Craft Spray Adhesive, which is either temporary or permanent, depending on how you apply it.

I applied the adhesive to the back of the mask, waited three to five minutes for it to be less tacky, then applied it to the rocket. Success! I got it on perfectly!!

|

| Doesn't look like everything's covered, because the edges are Scotch tape. But this was a masking masterpiece, guys. Perfectly aligned edges, full coverage... Great work. |

To seal the edges, I did a quick pass of the white paint first. Then, to my horror, the edges lifted away from the rocket and began to curl up. Gahh!!! Stop it! Stop it!!

There was no way around it - I'd have to stop my work, remove all the masking, and start again the next day.

I carefully peeled everything off, and laid the paper mask flat. It was a little wrinkled, but the edges were mostly fine, so when it was dry, I laid a book on top of it to flatten it out and left it overnight.

I figured I hadn't used enough of the spray adhesive. So the next day, as soon as I got home from work, I started again. This time, I made sure to get plenty of adhesive on all the edges, and reapplied the mask. Then I built up the whole brown-paper-and-tape masking apparatus and started again.

Here's where I grew impatient. I skipped the white sealing coat (not best practices, but not what led to disaster), and went straight for the red. And what a red! Rust-Oleum 2X Apple Red - bright, shiny, smooth... This rocket was looking beautiful.

I waited for about ten minutes, then began removing the mask. I pulled off the tape and the paper, and the fins were a brilliant white. The line was clean and neat. I pulled off everything but the paper mask... and then the mask wouldn't come off!

I used fingernails and lots of swearing, but the thing wouldn't budge. I even tried to gently, carefully slide the tip of my hobby knife underneath the mask to loosen it. Nothing!!

|

| Look at this monstrosity! |

|

| This obscenity!! |

|

| This abomination!!! |

After getting only tiny pieces of this mask off and gouging some of the white paint in the process, I took to The Rocketry Forum for help.

I went from happy to pretty desperate very quickly. What should I use? Water? Goo Gone? Razor blades?? After several more attempts to just coax the thing off, I'd scratched through in a few spots to primer, and in a couple tiny places down to the white body tube, and I worried I'd even gone through the glassine coating to the fibers below.

A lot of people suggested water (until I mentioned breaking through the tube - then it became too risky), WD-40, white vinegar. Problem with all of these is that the paint had made the paper pretty impenetrable.

Finally, in frustration, I got out a sheet of 220-grit wet/dry sandpaper and went to town on this rocket. Probably a terrible idea, I thought, but at this point, I don't care if the finish is smooth and beautiful - I just want that red paper OFF OF THERE!

Now, I don't have this next part documented with pictures, because I was acting in desperation. I wetted the sandpaper, and scrubbed like hell. Then, the sandpaper started breaking through the paint. Then through the paper mask. Then, I could see the white paper underneath!

I had three thoughts: 1) This is a terrible idea, and this paint job is ruined, but I don't care. 2) Wait... Is this working? I can't believe this is working!! 3) Holy crap! I can't believe this isn't causing more damage to the surface than it is!!

After scrubbing and scrubbing with the sandpaper, I finally got the paper mask off!! There was still some residue on the white part of the rocket, but the cursed red paper was gone!

|

| Flash! Aaaaaah! He saved every one of us! |

This is the point when Our Hero, inventor of the guillotine fin jig, rocketeer extraordinaire, stand up guy, and my Internet buddy Ted Macklin, posted those three magic words: Ronsonol lighter fluid.

According to Ted:

As long as this paint is sufficiently dry Ronsonol (which is actually naptha) will not dissolve the paint. It will soften and loosen most adhesives, especially those that are relatively fresh. A little Ronsonol on a cotton ball should work, but test first.Ronsonol? I think I have some of that!

So I searched in the depths of the darkest closet in my apartment, and found the Ronsonol. I dabbed some on a cotton ball, and began wiping down the rocket. Dudes, this stuff is AWESOME. Took the residue off so easily, and I could feel the smooth finish I'd started with below.

At this point, I was so happy, I did the Dance of Joy.

The rocket is on its way to greatness. I have some chips to repair, and I have to figure out how to safely mask off the red paint so I can retouch the white. But the ordeal is over. The Seal Team Six of rocket painting came through, and we are safely back on home ground - a little scarred, a little bruised, but safe for painting once again.

A Few Things I Learned From This

If you're a relative rocket n00b like me, here are a few things you might learn from my mistakes:

1. Paper masks = bad. Much better is a low-tack substance called Frisket Film. Also suggested possibilities would be vinyl drawer lining (though I'm not sure how low-tack that stuff is) and some kind of vinyl sign stuff. Still not sure exactly what this is called or where to get it.

1. Paper masks = bad. Much better is a low-tack substance called Frisket Film. Also suggested possibilities would be vinyl drawer lining (though I'm not sure how low-tack that stuff is) and some kind of vinyl sign stuff. Still not sure exactly what this is called or where to get it.

3. Maybe make a photocopy of paper parts you need if you might accidentally destroy them while making a terrible mistake? I'm not sure how I'm going to cleanly cut a mask for repairing the white part, now that the paper mask is dead.

4. Ronsonol lighter fluid safely takes off adhesive residue.

5. Don't be impatient. If I'd found out about the lighter fluid solution before attacking my rocket with a hobby knife, I would have no repairs to do. The stickers would be on it right now, and after nearly a month and a half building, the rocket would be done and ready to fly.

Wow!

ReplyDeleteGlad to see the Quad Runner turned out alright. Looks great!

Thanks! I had been procrastinating, as the compound fins intimidated me. But your advice really helped, and it wasn't as hard as I worried it would be.

DeleteI was unable to launch it yesterday, due to wind. But it's the rocket I'm looking forward to the most at the moment.

Terrific post. Great job on the Quadrunner.

ReplyDelete