Back to building the Big Dog, from Quest Aerospace...

After assembling the motor mount, I next decided to mark fin lines and a launch lug line - though I'll be using mini or micro rail buttons for this rocket.

If you're new to rockets, here's what I mean. Launch lugs were the standard for all hobby rockets until not too long ago. But in the last - I don't know for sure - decade or so, a lot of rocketeers have switched over to rail buttons. Instead of a thin, wobbly launch rod, which can suffer from wire whip if it gets too long for its diameter, mid and high power rocketeers often use something called t-slot rail to keep a rocket upright on the launch pad.

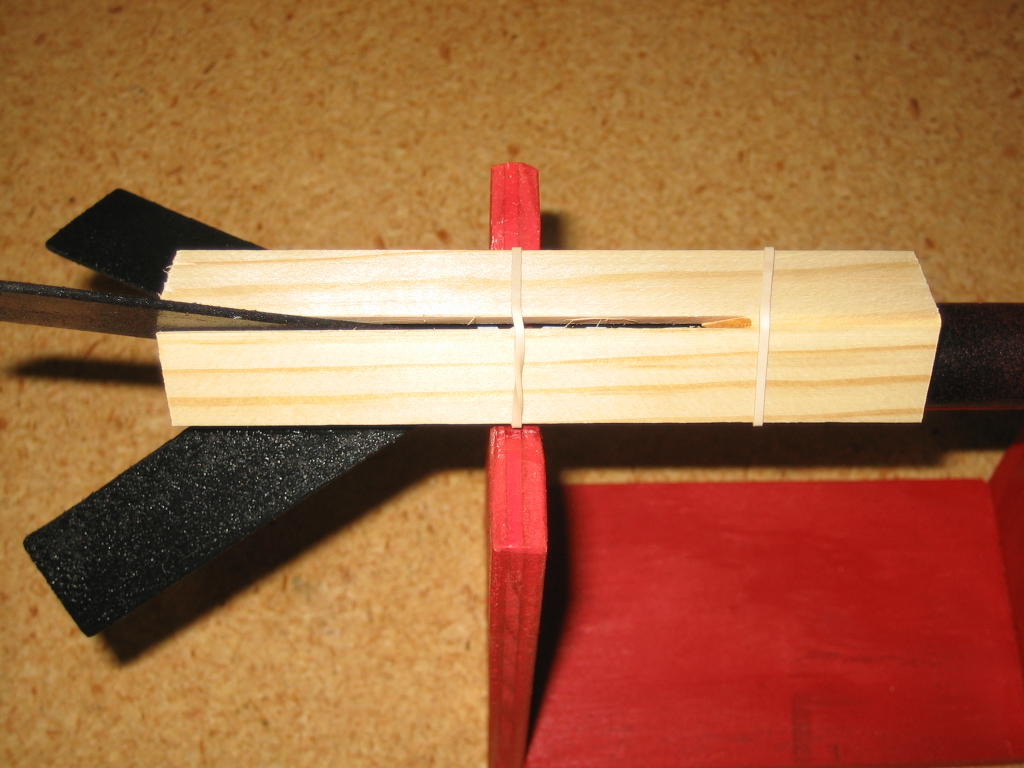

One of the most common rails used is a square aluminum extrusion, used to build all kinds of modular industrial things, with a cross-section that looks like this:

Instead of launch lugs, two (or sometimes more for really big rockets) small buttons are attached to the rocket, and they slide down into the slots in the rail. The result is a really sturdy launch platform.

| Launch button (bottom) fitting into a rail slot. Image from CoastRocketry.com |

I cut out the paper fin guide from the instructions, I carefully lined it up around the tube and taped it in place. There was a slight gap between the fourth fin line and the edge of the paper guide, which I figured was intentional. I marked each fin line with a little pencil dot.

Estes fin guides have an additional line, the launch lug line, exactly between two of the fin lines. The Quest guide didn't have that. In order to get the launch lug line exactly spaced between two fins, I folded the guide over and matched up to of the fin lines, then put a pencil mark on the fold.

Then I attempted to match up the fin lines with the little pencil dots on the airframe, and that's when I noticed a flaw in the kit - the dots didn't line up with the lines. I can only have noticed this because I must have laid the guide down between the first and fourth fins. I double-checked the lines with the other dot, and they all matched up. Something was off here!

A few months ago, I bought a digital caliper, because it was inexpensive, and because I figured I'd use it for... well, something. In any case, I like having precise measuring tools.

I got out the caliper and measured the diameter of the body tube. The box claimed the airframe was 1.92 inches. The caliper told a different story - 1.97 inches!

I knew this thing would come in handy!

I opened the free RockSim file for the Big Dog, available from Apogee Components. I don't have RockSim, but OpenRocket will open those files. I saw that, according the the sim file, the rocket should have an outer diameter of 1.97 inches. That's not much of a difference, but if the paper fin guide was made with a smaller diameter in mind, you'd get fins that are ever so slightly unevenly placed - all too close together, except for the first and fourth fin, which would be slightly too far apart. You might not even notice the difference unless you looked closely, but I look closely. It would have bothered me.

So, I used OpenRocket to print off a new fin guide - with an additional advantage that this one would already have a launch lug line marked.

I taped this guide to the rocket, and everything matched up correctly, so I marked all the lines.

Finally, I grabbed a length of aluminum angle and extended all the lines.

Normally, I extend the launch lug line all the way down the body tube, so I can sight along it and verify that I have the lug on straight. I keep the fin lines rather short. But, due to probably a little sloppiness on my part, I've gotten a few fins on not quite perfectly straight when using the Guillotine fin jig lately. The Guillotine is a great tool, but like all tools, you must use it with care.

Just to be sure I'm getting the fins on true, I extended the fin lines most of the way down the body tube. That way, I can check the fins are on the same vertical line on both ends of the fin jig before gluing them down.

You can see that before I did all this, I marked the tube spirals with a pencil so I could see the lines clearly when I filled them in.

The spiral groove on this rocket is really tight, and I had trouble in spots keeping the pencil tip in them. In spots, I couldn't even feel the groove with my fingernail. It's possible I could get away with just priming the rocket with a good coat of filler primer, but I don't want to get to the end of the build and see grooves. So I filled them in.

I didn't take any pictures of this process, but I just blogged about how I do it.

I filled the grooves, let them dry, then lightly sanded.

Next, I installed the motor mount and began airfoiling the fins. I'll talk about that in the next build post on this rocket.

Click here for Part 3.

Like my Facebook page for blog updates.