Now that your Skill Level 1 rocket is painted (and completely dry), it's time to finish building it - then you get to fly the thing!

If you've been following my posts here, you may get the impression that these things take forever to build. Actually, you can complete a Skill Level 1 rocket in a day or two - sometimes in as little as just a few hours (most of that is waiting for glue to dry). But I wanted to give you the details on how I build a rocket. I approach even easy rockets with care, so mine sometimes do take weeks, but that's only because I'm fussy and want a really nice end product. If you skip all the extras and just follow the instructions in the kit, you'll be done rather quickly, something you should probably do for your first rocket, so you don't get frustrated and quit before you see how awesome this hobby is.

OK, let's finish this baby up by adding the recovery system - this is how we get the rocket back safe and sound to fly again. All we have to do is attach the shock cord and parachute, and we're done!

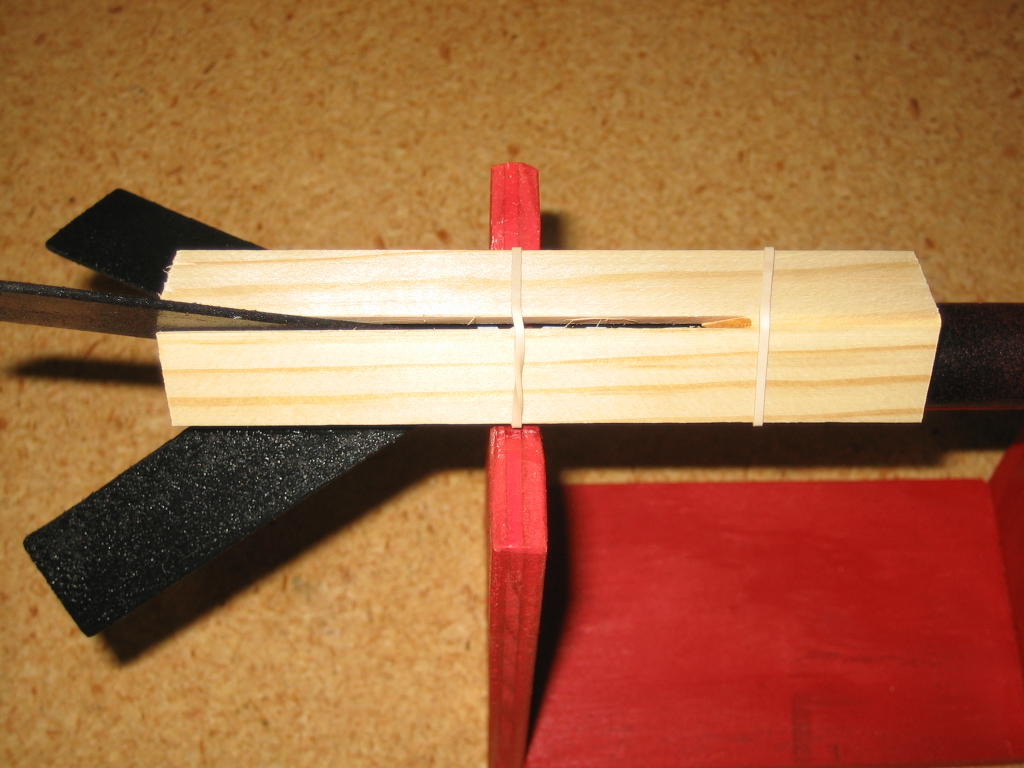

First, we're going to attach the shock cord - that's often a long, flat, rubber band-looking thing (or sometimes a thick, yellow Kevlar thread). We'll assume you're probably doing an Estes kit, like the Big Bertha, because that's what most people do. So, the rubber bandy thing.

Your instruction sheet will have an elongated trapezoidal shape divided into three numbered sections. That is the shock cord mount - you'll have to cut that out with scissors. Fold the two sides inward along the fold lines, so they'll crease easily when you glue the shock cord in.

Put a dot of wood glue in the middle area, and place one end of the shock cord in it, with the other end running out through the fat end. Fold the skinny end of the shock cord mount over the center part and press it so the glue spreads throughout it. Hold that in place a moment until the glue starts to set.

Next, place some glue onto the fat end of the shock cord mount where the cord itself is trailing out, and fold the middle/skinny ends over that. Press until excess glue squishes out the sides, and hold that until the glue starts to set.

Now you'll have a long shock cord secured into a tiny trapezoid of paper. Allow this to dry a little bit (I've moved too quickly here and the whole thing came apart because the glue hadn't properly set), but you don't need it to dry completely to move on.

You now have what's sometimes called a "tea bag mount," because if you hold the shock cord with the mount hanging down, it kind of looks like a tea bag.

The final step here is to place some glue into the body tube. Get a good dab of glue on the pad of your finger and spread it in one squarish spot on the inside of the body tube, about 1 1/2 to 2 inches from the top - no less. You need to make sure the shock cord mount is far enough into the rocket body to keep it from touching the nose cone when you insert it, or the cord might get in the way, and you won't get the nose cone on, because the fat shock cord won't leave enough space!

Wipe the excess glue off your fingers and place the shock cord mount down onto the glue, with the side the shock cord comes out facing the opening at the top of the rocket. Press this down and rub it around a little to make sure the glue spreads evenly and thinly under the paper shock cord mount. Hold it there a few moments until the glue begins to set, then let go.

Set the rocket on its side and allow the glue to dry for at least probably 20-30 minutes. Then, for good measure, use your finger to apply a thin layer of wood glue over the top of the shock cord mount to make sure you've got it good and sealed to the inside of the rocket.

Boom. Shock cord is now done. With the other end, you'll tie it to the loop of plastic in the base of the nose cone. Tie it well - a buntline hitch works, or just a simple double knot - and then you might put a dab of glue onto the knot to keep it in place.

|

| Tying a buntline hitch |

Let the shock cord mount and the nose cone glue (if you used it) dry completely, with the rocket lying on its side, and the nose cone lying separately - don't put the nose cone into the rocket at this point, or you might glue it on permanently, and you don't want that!

Once the glue is dry, it's time to attach the parachute. Probably the majority of basic kits use a parachute for recovery. Smaller rockets might use a simple streamer - a ribbon of plastic or paper which slows the rocket's descent enough that it won't be damaged. The streamer is pretty simple; you just tape one end of it to the shock cord. Other rockets might use some other form of recovery - tumble recovery, say, where the rocket comes apart and is so light it just falls to the ground in two pieces, and doesn't tend to get damaged.

But let's assume you have a parachute for now, like the Big Bertha has.

Skill Level 1 kits come with the parachute already assembled - you get a hexagonal chute with three shroud lines, each line attached to two corners of the chute.

The easy way to attach it to the nose cone is to hold the three lines together, form a little loop at the end, and thread this through the same loop of plastic in the nose cone to which you attached the shock cord. Pull the loop through, open it up with the shroud lines halfway through. Then you're going to pull the chute tight and pass it through the big loop and pull that tight - the chute will be attached to the nose cone.

|

| This parachute is tied directly to the nose cone - you can see how the shroud lines get tangled after a few flights. |

However, you might want to be able to remove the parachute between flights, and if you tie the chute right to the nose, you won't really be able to do that. It will quickly become tangled, and you won't get it untied. Parachute lines become tangled in ways that almost seem impossible to me. The lines are attached to the chute at one end and the nose cone at another, and yet, sometimes, I look at a parachute after a flight and ask How did those lines get tangled?? They crossed over each other! What is this sorcery??

Also, it's good for the chute to be stored separately from a rocket, hanging upside down, like from a pin in a cork board. The chute will be less likely to become permanently folded, so you're less likely to have it fail to open. A good way to attach a parachute is with a snap swivel. You get these where you find fishing equipment.

I love this aspect of rocketry - you find useful tools and materials where you wouldn't expect them to be, and you hack or adapt them to your purposes.

Just attach the chute to the closed loop of the snap swivel like you would to the nose cone, and when you want to attach everything to the nose cone, you just open the snap swivel and attach that to the nose cone.

All you do now is fold up your parachute, stuff it and the shock cord into the body of the rocket, and put the nose cone on top.

There are a number of ways to fold the parachute - some better than others. The instructions for the Estes kits aren't great - when I fold a chute like that for flying, they fail to open about half the time.

|

| Estes has you fold the top of the chute over and roll the sides in - not ideal for launching, as they don't open half the time (in my experience). |

We'll discuss parachute folding - with pictures - when we talk about launching. For now, you can roll the chute up like it says in the kit instructions.

Put the nose cone on, and look at your handiwork:

|

| The completed Estes Big Bertha rocket - tall and beautiful! |

YOU HAVE FINISHED YOUR ROCKET!

I hope any rocket n00bs out there have gotten some useful information from this Skill Level 1 tutorial series. This is just the beginning. There are a lot of cool tools and techniques, more advanced kits, higher skill levels, more powerful rocketry options and cool add-ons for rockets (payloads, multistage boosters, etc.). We'll get to all these on this blog, I hope. For now, build yourself a kit, fly it, and see if you like it. If you do, build a few more kits. When you get confident with your skills as a basic rocket builder, you're ready for something more challenging.

I've been doing this for only a little over three months now, and I've learned so much. There's a lot of fun stuff to do in rocketry, and things that seem way too complicated when you first start out are actually achievable. If you develop a passion for this, like I have, you can advance your skills and do things that will surprise you.

Take it slow. It's not a race. Have fun.

But here's a preview of something you might not yet think you can do - I certainly didn't when I started. This is a rocket I designed and built myself - and it's a two-stage rocket on top of that! I'll make a post soon about designing and building your own - something very satisfying, and not as complicated as you might think - it just takes a little time, the right tools, and some thought.

For now, though, here's a video of the first launch of my first "scratch-built" rocket, Janus I - named for the two-faced Roman god of beginnings and change. I hope you enjoy.