This is a continuation of a series on model rocket stability for beginners. Click here to go go the beginning of the series. Click here to read the last post.

Last time, we discussed the earliest method of finding the Center of Pressure (CP) on a model rocket - the cutout method. This simple method ensured stable flights on every model in the early days of model rocketry. Finding the CP is a crucial problem to solve, because in order for stable rocket flight, the CP must be behind the Center of Gravity (CG).

But, of course, the cutout method had drawbacks. Rocketeers had to be reasonably skilled at drawing an accurate representation of the rocket on stiff paper or cardboard, with all the parts in correct proportion. In other words, in order for the cutout method to work the drawing had to look just like the real thing.

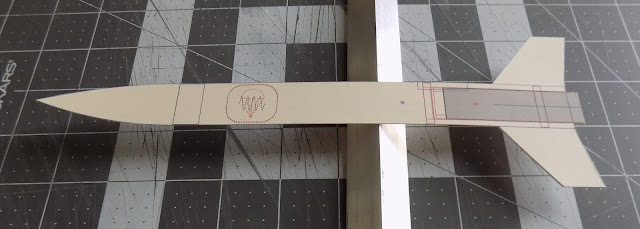

Since I'm not a skilled draftsman, I cheated a little. I illustrated the cutout method with a design I'd created in OpenRocket - Sounder IB - which I printed on heavy card stock, cut out, and balanced on a piece of aluminum angle.

This showed us another drawback of the cutout method - accuracy. While balancing the two-dimensional cutout of Sounder IB did find the center of area for the rocket, that point was far forward of the red CP mark on the drawing itself. In other words, OpenRocket told me that the CP was in one spot, but the cutout method indicated that the CP was a good two inches further forward. So far, in fact, that the CP as determined by the cutout method was in front of the CG, as calculated by OpenRocket.

So, while the OpenRocket design showed the rocket to be perfectly stable, the cutout method showed me a dangerously unstable rocket - one which would flip violently around if it were launched!

So, does the cutout method represent the Center of Pressure at all? Or were rocketeers merely fooling themselves? And how do we - how does OpenRocket - know where the CP actually is? Who's right, who's wrong, and why?

The answer is that they're both right - kind of.

In the cutout method, we're balancing a 2D representation of the rocket - on its side. The cutout is resting on its balance point, so as the force of gravity pulls on it, the force is equally distributed in front of and behind the aluminum angle. This force - gravity - is acting a substitute for another force - air pressure - in the real rocket. So, for the cutout method to represent reality, the air pressure would have to be hitting the rocket directly from the side. The cutout method shows you were the CP would be if the rocket were flying sideways!

In this case, that means that all the air is hitting the rocket from the side - at an angle of 90 degrees. The angle the wind is hitting a rocket is known as angle of attack.

|

| Alpha represents the angle of attack. Image from Centuri TIR-30, by James Barrowman. |

In The Handbook of Model Rocketry, a 90-degree angle of attack is described as "the worst possible flying condition." In fact, it's an imaginary flying condition, because rockets do not fly sideways. They fly pointy end first!

Under normal flying conditions, with the proper motor (providing enough thrust for the weight of the rocket), model rockets fly at or near zero degrees angle of attack. While the ambient wind tends to blow horizontally along the ground, the rocket flies fast enough upward that the effect of the wind is minimized. If the wind on launch day is, say, 8 miles per hour, and the rocket is flying upward at, say, 200 miles per hour, the rocket will barely notice the wind coming from the side.

Under those conditions, the determination of the Center of Pressure is dominated much more by the fins and nose cone than by the surface area of the body of the rocket. As the rocket wobbles during flight - totally normal for a model rocket - the angle of attack will swing back and forth between zero and a few degrees. As this happens, the fins, which stick out from the body of the rocket, use the oncoming air pressure to correct the rocket's path, causing the back end to rotate away from the wind.

The pressure on the body tube at or near zero degrees angle of attach is much lower, and has much less effect on the CP.

But if the angle of attack were to suddenly increase significantly, then the air pressure on the nose cone and body tube becomes much more significant. The effect is that, at high angle of attack, the Center of Pressure moves forward. If, due to some (imaginary) catastrophic event in flight, the rocket were to fly sideways, then the CP would move forward enough that it would be where we see it when we do the cutout method.

|

| As angle of attack increases, the influence of the nose cone and body tube increase - the CP moves forward! Image from Centuri TIR-30, by James Barrowman |

There are only two situations I know of when a normal rocket experiences these conditions. The first is when the rocket is sitting on the launch pad, and the breeze is blowing across the field. But when the rocket is sitting still on the pad, it's not flying, so this doesn't count.

The other is a rare, pretty strange event, which I've seen twice - recovery.

Once in a while, a rocket will launch, fly to apogee, and then due either to an ejection charge failure or a nose cone which is stuck on too tight, the nose cone doesn't eject. The rocket stays intact, the parachute does not come out, and the rocket begins to fall back to Earth.

Normally, when this happens, it's pretty frightening. Because the rocket is stable, with its CG in front of its CP, it will tend to fly nose first. So a rocket which has an ejection failure usually comes in ballistic - taking a nose dive straight at the ground with increasing speed. This usually destroys the rocket.

Sometimes, very rarely, an odd thing will happen. The rocket will go up, tip over at apogee, and begin falling back down. In rare instances, the CP at 90 degrees angle of attack will be the same spot as the rocket's CG. The rocket is then neutrally stable. The forces of gravity and air pressure are both centered on the same spot. The rocket descends sideways. Since the Center of Gravity is the point of rotation, and the Center of Pressure is the balance point of the force of the air of the rocket, the whole thing is in balance - just like a balanced scale.

|

| If she weighs the same as a duck... |

Both times this happened, the rocket fell very slowly, and came to a soft landing. Both times, I was filming, but both times, I was so stunned, I missed getting the slowly descending sideways rocket in frame. But it was pretty cool - and certainly a relief not to have the rocket come in ballistic.

I should mention that you shouldn't try to replicate this, by gluing on a nose cone or something. It's a chance event when it happens, and the same rocket might not do it twice - a slight difference in Center of Gravity could change everything, and the rocket would come in ballistic. But if you do see it, it's kind of amazing.

* * *

The fact that the CP can shift forward is really important. It means that the CG and CP could be too close together for the rocket to remain stable. If the angle of attack suddenly increases, due to a gust of wind, or off-center thrust of the motor, or any number of things, having the CG too close to the CP means that under certain circumstances, the CP could move forward of the CG! If these two switch position, you now have a dangerous, unstable rocket.

This brings us to the question How far forward of the CP chould the CG be? I was going to save this for a later part of this series, but I think it makes sense to mention it here.

This brings us to the question How far forward of the CP chould the CG be? I was going to save this for a later part of this series, but I think it makes sense to mention it here.

In general, the rule of thumb is that the CG should be at least one body tube diameter ahead of the CP. That means that if the rocket is, say, 1 inch in diameter, the CG must be at least 1 inch forward of the CP. This margin is known as caliber, and refers to the diameter of the rocket.

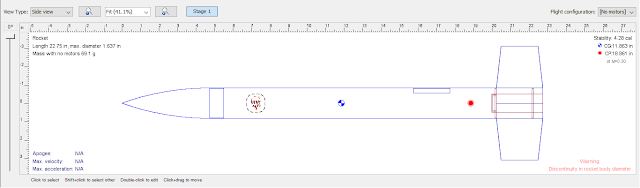

Sounder 1B is 0.976 inches or 24.8 millimeters in diameter. If the CG is exactly 0.976 inches or 24.8 mm ahead of the CP, we say the rocket has a stability margin (sometimes called the static margin) of 1 caliber. If the CG and CP are 1.952 inches or 49.6mm apart - twice the diameter of the body tube - the margin is 2 caliber.

As you see, Sounder 1B has a static margin of 1.63 caliber. The CG is 40 millimeters forward of the CP. Since the minimum static margin is 1 caliber stability, this is fine. The ideal, especially if you want to fly as high as you can, is a static margin between 1 and 2 caliber. More is usually OK, up to a point. Less is generally not enough for safety, except in the case of some short, stubby rockets.

For most model rockets, however, the minimum safe static margin is 1 caliber. Having a static margin of 1 caliber or more ensures that, even if the rocket encounters a high-degree angle of attack for a moment, the CP isn't likely to shift forward of the CG. The rocket should remain stable.

* * *

To be clear, the cutout method does work to make stable rockets. But it's what we could call overly conservative with its CP location. A rocket designed using the cutout method would certainly be stable and safe, but it errs so far on the safe side, that you may end up building rockets which are far heavier in the nose cone than they need to be, or with more fins or larger fins than you need. That means you may rob yourself of performance, or you may shy away from building a rocket which is perfectly safe and stable, because you worry it might not be.

A better, more accurate method of finding the Center of Pressure was called for. We'll discuss that method in the next post.

Click here for Part 5.

Follow me on Twitter.

Like my Facebook page for blog updates and extra stuff.

Have a question you'd like to see addressed on this blog? Email me at iamtherocketn00b@gmail.com.

Click here for Part 5.

Follow me on Twitter.

Like my Facebook page for blog updates and extra stuff.

Have a question you'd like to see addressed on this blog? Email me at iamtherocketn00b@gmail.com.