Some rocketeers have such good modeling skills, it's intimidating. Scale modelers working on tiny details can make a relative beginner feel like I have no idea how to do that. I'll never be that good. But that doesn't mean you can't try - things might turn out better than you expect, and the only way to get good at it is to do it.

I decided to try making chain drive covers, or servo pods, for the Estes V2. This isn't part of the kit, and making little parts is a real challenge for me. Tiny stuff frustrates me.

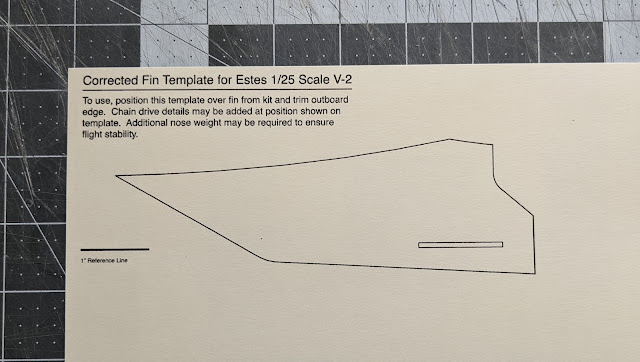

I decided to see if I could make these little details well enough to bother putting them on the rocket. These were done by eye, without much reference material, apart from some photos on the Internet and Peter Alway's Rockets of the World. I used leftover fin material to cut rough shapes I'd sand into the final form.

The kit fins are 3/32 inch thick, and these pods are surely not to proper scale. The fin stock is probably too thick, for one thing. They're also probably not shaped just right. But as I said in a previous post, I'm not going to be a stickler for scale accuracy. If they look pretty good and add to the model, that's good enough for me.

The pods are taller on one end than another. Stack sanding them all to the same shape was tricky. Once they all went flying and I found most of them, but had to cut an extra.

After cutting the rough shape out and sanding them all, I began by rounding the ends. Then I carefully rounded them over the tops.

Using a sanding block turned out to be really difficult, so I switched to a scrap of 400 grit sandpaper on my finger to do the rounding.

In the close-up photo you can see the imperfections, but really these turned out pretty good.

Without the extreme close-up, you don't really notice the inconsistency of shape. I decided to try gluing them on

They turned out great! True, they're not perfectly to scale, but I really feel they add something to my V2.

I ended up using Titebond Molding and Trim Glue to attach the pods to the fins. I usually use this white wood glue for fillets, and Titebond II for the rest of the build. But the Molding and Trim Glue worked out better in this case. Its "fast initial tack" helped in that I could place the chain drive pods in place with tweezers, and after a minute or so, press the piece down tight to the wood without it accidentally slipping out of place. Seems like a great choice for a piece you don't want to move around too much after placing it. I might start reaching for this stuff more regularly.

That said, the answer to the perennial model rocket newbie question "what's the best glue" is "pretty much any white or yellow glue." Even School Glue isn't as bad a choice as some people think (although I wouldn't use it). Use what you want.

Except for hot glue. Never use hot glue for model rockets.

After gluing these on, I ran two layers of Titebond Molding and Trim Glue fillets all the way around them. This will help make the pods look like a single piece with the fins, and hide any edges where the glue doesn't go all the way to the edge - so there won't be a visible gap when you paint.

Like my Facebook page for blog updates and extra stuff.

Have a question you'd like to see addressed on this blog? Email me at iamtherocketn00b@gmail.com.