Fortunately, I have OpenRocket - free rocket design and simulation software.

As any gamer or couch potato can tell you, even if you're really tired, you can still spend hours fiddling around on your computer.

So, when I don't have the time or energy to build rockets or write about them, I play around with different designs. It's a way of staying an active rocketeer when I'm too busy to be actually building.

Once you know the basic principles of stability and rocket construction, it isn't that hard to design a basic rocket - or at least to get one started. You might need to make revisions, weigh components and change a few things, but you can come up with some cool basic designs in short order. I've even built and flown rockets that took me 20 minutes to conceive, and I only had to make minimal revisions.

Here are some designs I've been working on.

The Circe Series

I started this the other night. I wanted something simple to replace my lost Estes Hi Flier - a small, lightweight, high-flying rocket. It performs so well because it's a minimum diameter rocket - meaning it is only as big around as it needs to be to hold the motor. It has no motor mount - the body tube is the motor mount!

|

| Circe A - a small rocket which will hold a standard 18mm diameter (A-C) motor, and go quite high |

Though I am trying to build bigger and bigger rockets (and currently building two of my Estes Pro Series II rockets), I just had the urge to design this little thing.

OpenRocket has a scale function, so you can take a rocket of a particular size and scale everything up or down by the same amount. So while Circe A (pictured above) will only take a C sized motor, Circe B looks exactly the same, but is larger and will take a D or C motor. When you scale things up in OpenRocket, sometimes you have to adjust components, because, for example, the mass of the nose cone might actually end up being much greater than the part you actually have on hand. Other than that, it's pretty simple.

I went up to a BT60 sized rocket with the Circe series before going to bed. BT60 is a 1.637 inch diameter tube, and is the same size as the Big Bertha. The cool thing about the BT60 is that it's just the right size to fit a cluster of 3 standard motors.

If you're an advanced rocketeer and are good at making stuff from scratch, you can make your own parts. All of them - even the body tubes. And, of course, nose cones.

I'm not to that level yet. I don't have access to a wood lathe, and I haven't picked up the skill of designing and making a custom-shaped nose cone. Fortunately, there are a lot of good parts on the market.

So what I do, for now, is look at the parts that are available - either in my parts box, or online, and design around that.

Here's a lovely balsa wood nose cone I picked up from JonRocket months ago.

This shape is a spherically blunted tangent ogive, and the nose cone fits a BT70 tube, which is about 2.2 inches in diameter. This is getting toward the higher end of body tube size you'll find for low power model rockets, and into the mid power range. If you're new to model rockets, this thing will look huge to you - there are not many BT70 kits out there!

I have realized I need to get more of these, or get some other BT70 nose cones, because over the months, I've designed a number of rockets around this very nose cone.

One of the first was called Horus.

The Horus Series

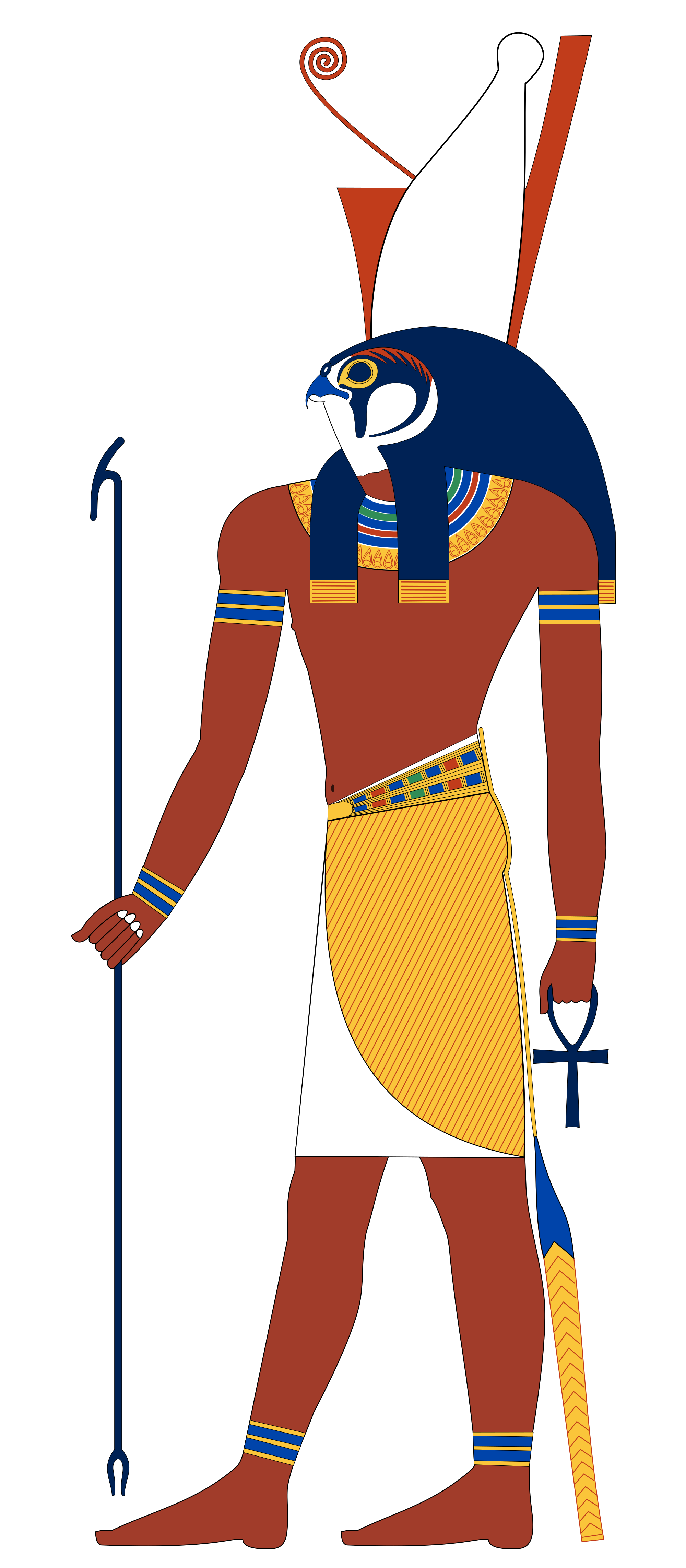

People give rockets all kinds of zany names. A quick look at an Estes catalog gives you some idea - Sizzler, Prospector, HiJinks, etc. A rocket can have any kind of name. But I guess I'm more of a classical kind of guy. I like to name my rockets after Greek, Roman, or sometimes Egyptian gods or mythological characters, or after celestial bodies. Horus is the falcon-headed Egyptian god of the sun.

Seemed like an appropriate name for a rocket.

I wanted to design my own rocket which looked vaguely like the Sirius Rocketry Eradicator - a beautiful rocket which has been on my wish list since I first saw it - but would be simpler to design and construct for a n00b.

|

| The Eradicator, from Sirius Rocketry, available here |

(Eradicator - there's an interesting one. I love this rocket, but the name reminds me of this Kids In the Hall sketch)

No offense, Sirius Rocketry - you guys are awesome!

Anyway, I love the two differentiated diameters of the airframe on the Eradicator. I designed this one:

Not too bad, I thought. But in order to get a minimum of 1 caliber stability, I needed to have 5 fins, if they were to be swept forward. I was able to decrease the number of fins to four by adding fin vanes.

This increases the surface area of the fins, moving the center of pressure aftward, without making the fin span inordinately wide.

The Eradicator has a lot of great detail - it looks like a real launch vehicle. That level of design was a bit advanced for me. That's not to say you can't add additional detail to the build, but it's tricky to add it to the OpenRocket design.

FMLV

This is a simple recent design, but one I like and am building now. It's another BT70 design with a 24mm motor mount. Like the Circe rocket, it's got swept back fins, but as you'll notice, the tips are not parallel to the rocket.

I've seen a few designs like this recently, and I like the look of it. Actually, a lot of classic kits have fins like this, but I've only just recently thought of changing the shape of the fins in OpenRocket.

You can select a few basic fin shapes in OpenRocket. I almost always opt for "trapezoidal," and then simply change the dimensions of the root chord, tip chord (chord is the distance from the leading edge to the trailing edge) and height (the distance from the airframe to the tip of the fin).

That means that most of my designs look like this:

|

| Imperius, formerly known as the "Donor's Rocket" |

See how the tips of the fins are parallel to the rocket body tube? Nothing wrong with that, of course.

But part of what gives a rocket its character is the shape of the fins. I went with a few designs that had the fins swept forward, like the Horus series above, and the Copperhead (formerly known as "Keith's Rocket").

And I like these designs. But you learn by playing with the tools you have, so I decided to try a different shape. Still simple enough to cut with a ruler and hobby knife, but a little different from what I'd made before.

FMLV stands for First Massachusetts Launch Vehicle, because it's the first scratch design rocket I'm building here in Boston. I'm using a 24mm Estes "quick release" screw-on motor retainer so that I can use my newly-acquired AeroTech 24mm reloadable casing, or an Estes black powder D or E motor.

That gives me a lot of motor options.

It will also be the first rocket I build from scratch which will have through the wall or TTW fin construction. This means that the fins have tabs at the base which will go through slots in the airframe and attach directly to the motor tube. You fins this as pretty standard in mid power and high power kits, and even some Estes low power kits, like the Cosmic Explorer.

|

| Attaching fins to the Cosmic Explorer. In this kit, the slots are already cut for you. |

Of course, in a kit, the slots are cut for you. For the FMLV, I'll have to cut my own fin slots for the first time.

BT80 Rockets

Also included in my parts box is a BT80 sized parabolic nose cone.

You may have noticed that this nose cone has a similar profile to the Big Bertha nose cone, but while the Bertha uses a BT60 body tube - 1.637 inches in diameter, the BT80 is 2.6 inches in diameter. For a beginning model rocketeer, that's really big!

Regular readers of the blog may also recognize this nose cone as part of the ICU2 camera payload bay from Make: Rockets: Down-to-Earth Rocket Science by Mike Westerfield, which I used in the design of the Janus II two-stage rocket.

Since I had another one, I played around a little with a few designs.

A really large rocket, called Titus, after my girlfriend's nephew.

Meh... This kid needs to have a cooler looking rocket named after him.

Also played around with a large two-stage rocket.

Could be fun, especially with the two large 24mm diameter motors. But still a little inelegant. It was probably late at night when I did this one.

I might make a larger, not-quite-proportional version of the Copperhead rocket pictured above.

Of course, the Janus II with its payload bay was lost on first flight, so I may just rebuild that...

Finally, a design I nearly forgot about. This must have been months ago.

A really large rocket, called Titus, after my girlfriend's nephew.

Meh... This kid needs to have a cooler looking rocket named after him.

Also played around with a large two-stage rocket.

Could be fun, especially with the two large 24mm diameter motors. But still a little inelegant. It was probably late at night when I did this one.

I might make a larger, not-quite-proportional version of the Copperhead rocket pictured above.

|

| A larger Copperhead design with the BT80 nose cone, and a 29mm motor mount, for E, F or G motors |

Finally, a design I nearly forgot about. This must have been months ago.

Arrowhead

I had this idea when building both Sounder I, a tiny minimum diameter rocket I lost on its first flight, and the Ceres B booster, again from Mike Westerfield's book.

I stacked one on top of the other with a balsa transition I had in the parts box.

It reminded me of some of these:

This looks like a two-stage sounding rocket, but it's really just one stage. Not that you couldn't do a two-stager here, but it would require some electronics I haven't worked with just yet.

I haven't discussed staging on the blog yet, but in brief, most model rockets with multiple stages rely on the first motor igniting the second. The first motor has no delay grain or ejection charge, or even clay cap.

|

| From Apogee Components |

The propellant is exposed at the forward end of the motor, so when it burns up, hot particles shoot forward into the nozzle of the second motor, igniting the second stage propellant.

|

| An illustration of model rocket motor staging from the Estes Model Rocketry Technical Manual |

Many multi-stage rockets have the motors touching each other. This is known as contact staging. There can be a gap between them, in what is known as gap staging, but the gap can only be so wide - 12 inches is probably the maximum.

This rocket is longer than that, and the two parts are separated by a solid balsa transition, so there would be no way for the hot propellant particles to reach the top portion. You can make hollow paper transitions, but I'm not very good at that yet, and balsa transitions of all sizes are available online.

Again, for a beginning designer, working around available components is the easiest way to get started.

High power rocketeers do multi-stage rockets using altimeters, or sometimes timers, to electronically ignite upper stages in the air. This is known as an air start.

Still, even as a one-stager, I like it.

Like my Facebook page for blog updates.